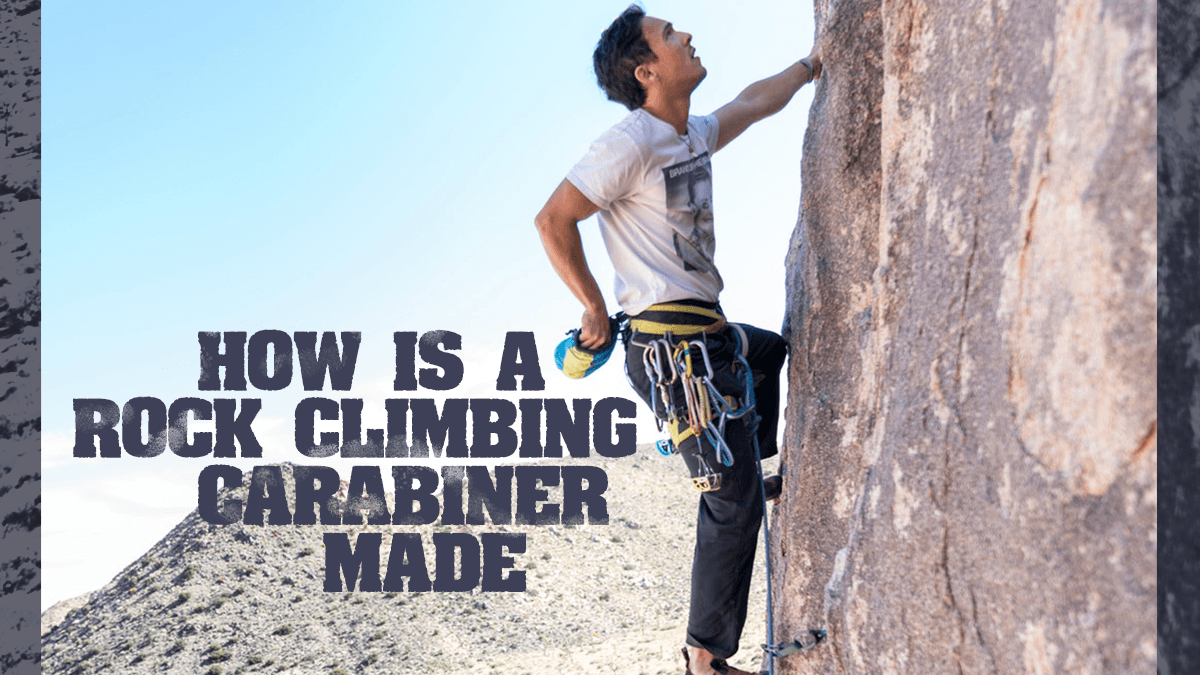

How is a Rock Climbing Carabiner Made?

A rock climbing carabiner can handle over 4000 pounds at its maximum capacity.

Even so, it’s one of the essential rock climbing equipment a climber uses. You may have wondered if you can really trust such a small piece of metal to save your life.

Fortunately, you came to the right place. Keep reading to find out how rock climbing carabiners are made and what makes them so strong.

Building a Rock Climbing Carabiner

All carabiners start off as a tube of an extruded aluminum alloy called rod stock.

Aluminum and zinc are combined to form a strong light metal. It’s this strength that’s built-in at a molecular level that makes rock climbing carabiners able to support so much weight.

A machine then bends the stock into a rough oval shape. Next, a forging machine presses the carabiners to form the final template. A trim removes any excess metal.

Carabiners are heated again to strengthen the metal alloy. Once they cool off in water, the carabiners are passed through vibrating drums. There, they’re tumbled with wet rocks to remove any unwanted rough texture.

This smooth texture is essential for avoiding damage to ropes as they pass through it.

After that, the other pieces are added that allow it to be clipped onto things.

Carabiner Shapes

There is a wide variety of carabiner shapes, and each of them has advantages and disadvantages.

The most common carabiner shape is the D-shape. It has a straight spine and sharp bend at both ends of the carabiner. It cuts down on equipment weight but increases strength.

The oval-shaped carabiner has a more old-school look. They are typically cheaper and durable but slightly weaker and heavier than the D-shaped carabiners.

The pear-shaped carabiner has sides that angle away from the bend to form a bigger and curvier rope basket. They are larger and therefore heavier, so they’re best saved for a single belay or anchor.

Carabiner Parts

There are essential parts which make up carabiners:

- Gate: The part of the carabiner that opens and snaps shut.

- Nose: The part of the carabiner into which the gate snaps, closing the loop.

- Spine: The long side of the carabiner opposite the gate.

- Basket: Often the more prominent of the two bends in the carabiner shape, and where the rope or gear sits when clipped.

When all these parts work together, they’re safe to use for rock climbing.

Carabiner Testing

Every batch of carabiners is tested after they’re made. A tensile tester slowly pulls the carabiners until they fail. Carabiners must withstand a minimum of 20 kN or 4,900 pounds along with the major axis.

Other tests may also be performed that mimic real-world settings to ensure safety in all situations, like in rock climbing falls.

Companies use manufacturing statistics and benchmarks to ensure more than 99% of all the carabiners produced are stronger than necessary and safe for users.

Want to Learn More About Rock Climbing Gear?

You now have everything you need to know about how rock climbing carabiners are made and what makes them so strong.

If you are a beginner climber, you may be looking for information about the equipment you need. Check out this article about what climbing gear you should get to get started in this hobby!